Post Processing

Post-processing and added value capabilities can significantly enhance the functionality and performance of biomedical textiles.

Post processing capabilities

Post processing capabilities

-

Enhanced Durability

-

Customization and Shaping

-

Functional Integration

-

Sawing

-

Fabric shape setting

-

Fabric laser cutting

Post processing capabilities

-

Enhanced Durability

Enhanced Durability

-

Sawing

Sawing

-

Customization and Shaping

Customization and Shaping

-

Fabric shape setting

Fabric shape setting

-

Functional Integration

Functional Integration

-

Fabric laser cutting

Fabric laser cutting

Post processing capabilities

-

Enhanced Durability

Enhanced Durability

-

Sawing

Sawing

-

Customization and Shaping

Customization and Shaping

-

Fabric shape setting

Fabric shape setting

-

Functional Integration

Functional Integration

-

Fabric laser cutting

Fabric laser cutting

Post processing capabilities

-

Enhanced Durability

-

Customization and Shaping

-

Functional Integration

-

Sawing

-

Fabric shape setting

-

Fabric laser cutting

Antimicrobial Treatments

Applying treatments to prevent microbial growth and infection, crucial for many medical applications.

Hydrophilic/Hydrophobic Coatings

Enhancing the fabric’s ability to repel or absorb moisture, which can be important for wound dressings or other applications.

Sterilization

Ensuring the textiles are free from pathogens and suitable for medical use, often through methods like autoclaving, gamma irradiation, or ethylene oxide treatment.

Bioactive Coatings

Incorporating substances that promote tissue growth or interact beneficially with biological systems, such as drug delivery systems or growth factor coatings.

Controlled Release Systems

Designing textiles that can release therapeutic agents or drugs over time, useful for applications like wound care or implants.

Aesthetic Finishes

Adding color, patterns, or other visual elements to meet patient or market preferences while maintaining functionality.

Biodegradable or Eco-friendly Treatments

Using materials or processes that minimize environmental impact, which can be an important consideration for sustainability.

These added capabilities can make biomedical textiles more effective, user-friendly, and suitable for a wide range of medical applications.

By choosing the appropriate technique—knitting, braiding, or weaving—and carefully selecting the biomaterials, you can tailor the textile’s properties to match the requirements of the surgical application.

Each processing method and material

offers unique benefits

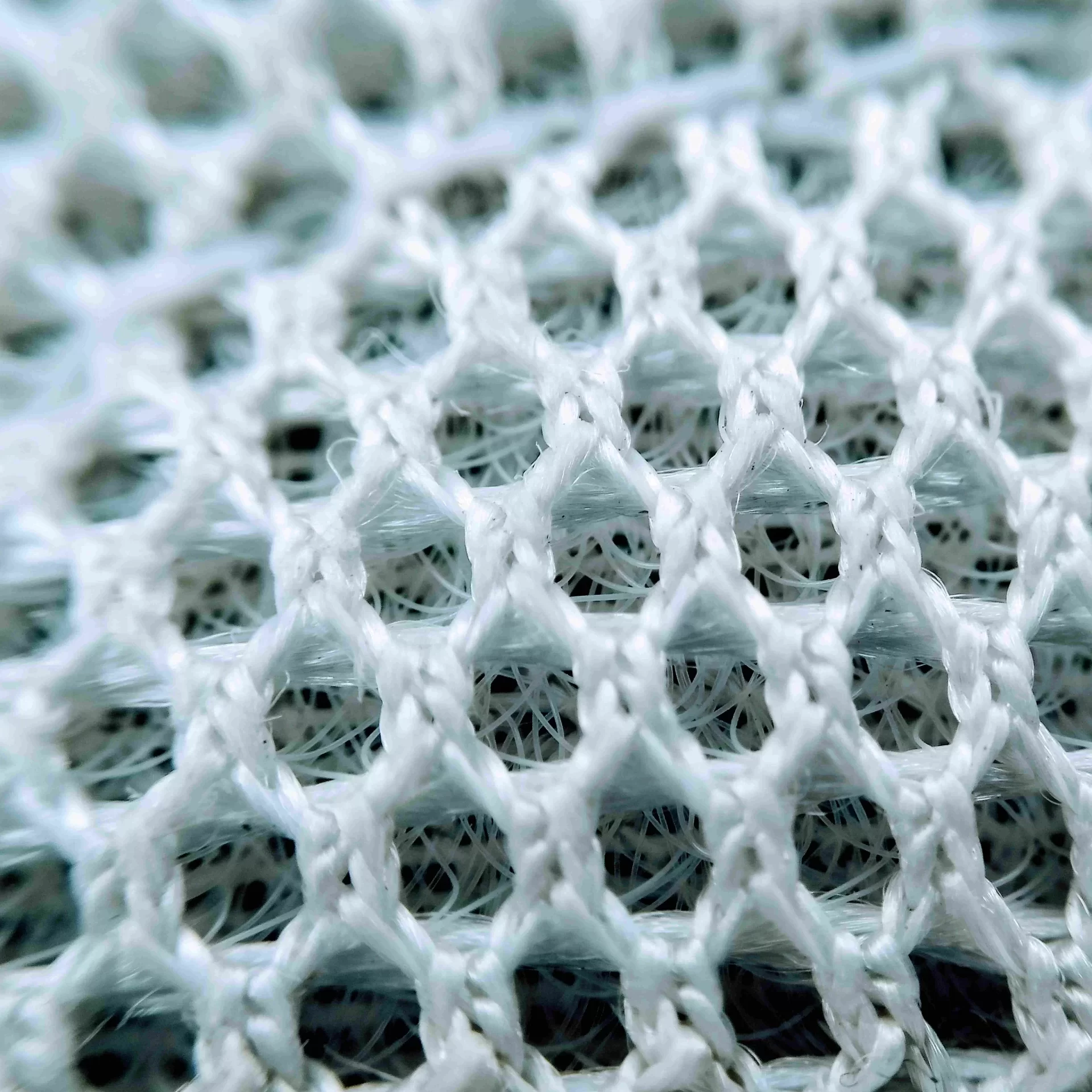

Knitting

Provides flexibility and elasticity, which can be useful for fabrics that need to conform to various shapes or move with the body.

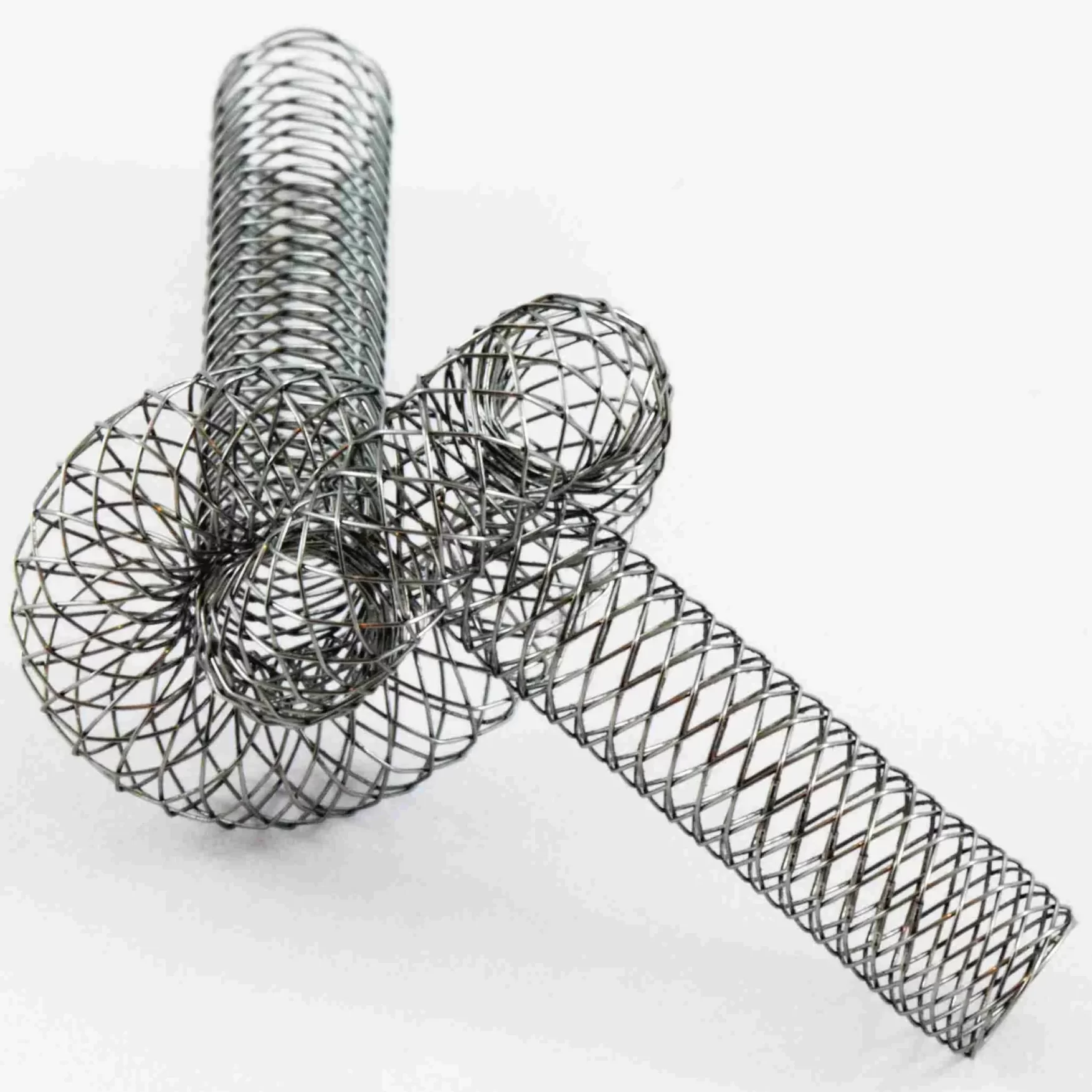

Braiding

Often used for its strength and durability, making it suitable for high-stress applications or structural components in implants.

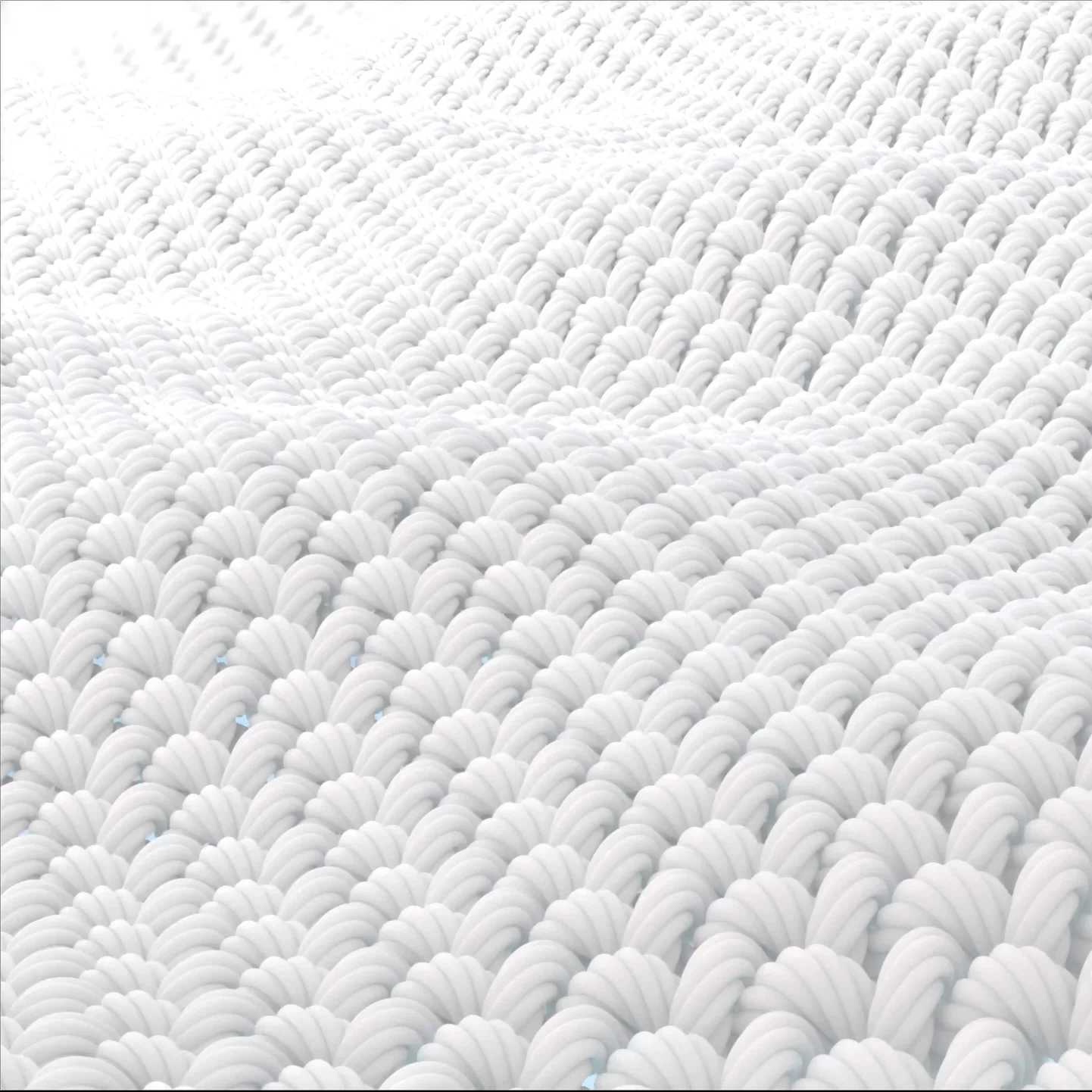

Weaving

Allows for intricate patterns and structural integrity, which can be advantageous for creating supportive or reinforcement layers.

Post-processing solutions further enhance the textiles, providing additional features like antimicrobial properties, controlled drug release, or improved biocompatibility. Combining these techniques and treatments helps achieve the desired performance and safety for implantable medical devices.

These added capabilities can make biomedical textiles more effective, user-friendly, and suitable for a wide range of medical applications.

By choosing the appropriate technique—knitting, braiding, or weaving—and carefully selecting the biomaterials, you can tailor the textile’s properties to match the requirements of the surgical application. Each processing method and material offers unique benefits:

Knitting

Provides flexibility and elasticity, which can be useful for fabrics that need to conform to various shapes or move with the body.

Braiding

Often used for its strength and durability, making it suitable for high-stress applications or structural components in implants.

Weaving

Allows for intricate patterns and structural integrity, which can be advantageous for creating supportive or reinforcement layers.

Post-processing solutions further enhance the textiles, providing additional features like antimicrobial properties, controlled drug release, or improved biocompatibility. Combining these techniques and treatments helps achieve the desired performance and safety for implantable medical devices.

These added capabilities can make biomedical textiles more effective, user-friendly, and suitable for a wide range of medical applications.

By choosing the appropriate technique—knitting, braiding, or weaving—and carefully selecting the biomaterials, you can tailor the textile’s properties to match the requirements of the surgical application. Each processing method and material offers unique benefits:

Knitting

Provides flexibility and elasticity, which can be useful for fabrics that need to conform to various shapes or move with the body.

Braiding

Often used for its strength and durability, making it suitable for high-stress applications or structural components in implants.

Weaving

Allows for intricate patterns and structural integrity, which can be advantageous for creating supportive or reinforcement layers.

Post-processing solutions further enhance the textiles, providing additional features like antimicrobial properties, controlled drug release, or improved biocompatibility. Combining these techniques and treatments helps achieve the desired performance and safety for implantable medical devices.