Overview

Overview of Biomedical Textiles

Biomedical textiles are engineered fabrics specifically designed for medical applications, ranging from external wound care to implantable devices. These textiles are developed using advanced techniques like weaving, knitting, and braiding, creating structures that meet strict biocompatibility and performance standards.

Key Applications

- Implants: Textiles used in hernia repair, cardiovascular devices, and tissue scaffolds.

- Wound Care: Materials that promote healing and protect injuries.

- Drug Delivery: Fabric that integrates medication for localized treatment.

Materials

Biomedical textiles are made from various biomaterials, including synthetic polymers (e.g., polyester, nylon, and PTFE) and natural fibres (e.g., collagen, silk).

These materials must ensure biocompatibility, durability, and mechanical properties suited for specific medical purposes.

Some textiles are designed to be bioresorbable, breaking down in the body over time.

Manufacturing Techniques

Manufacturing Techniques

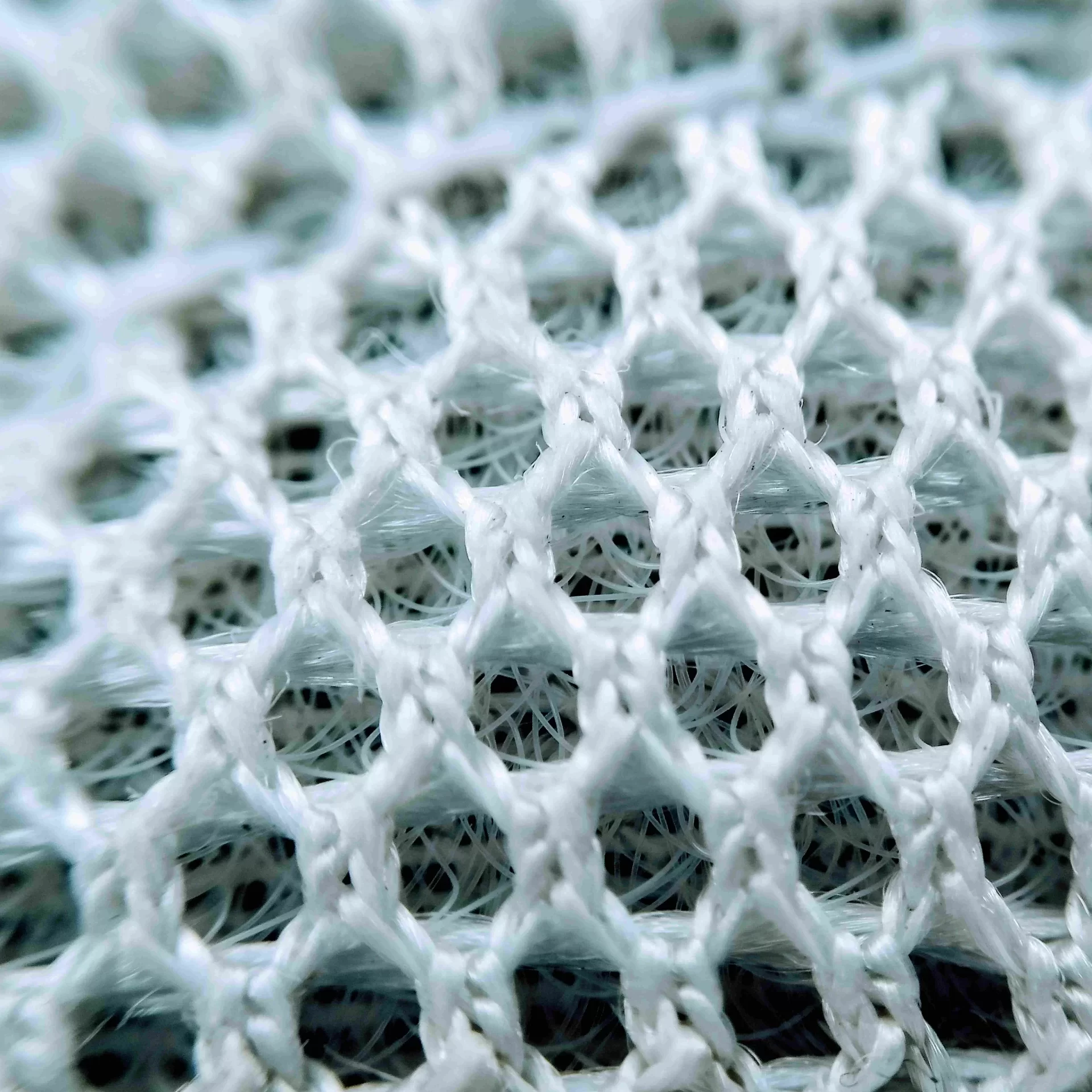

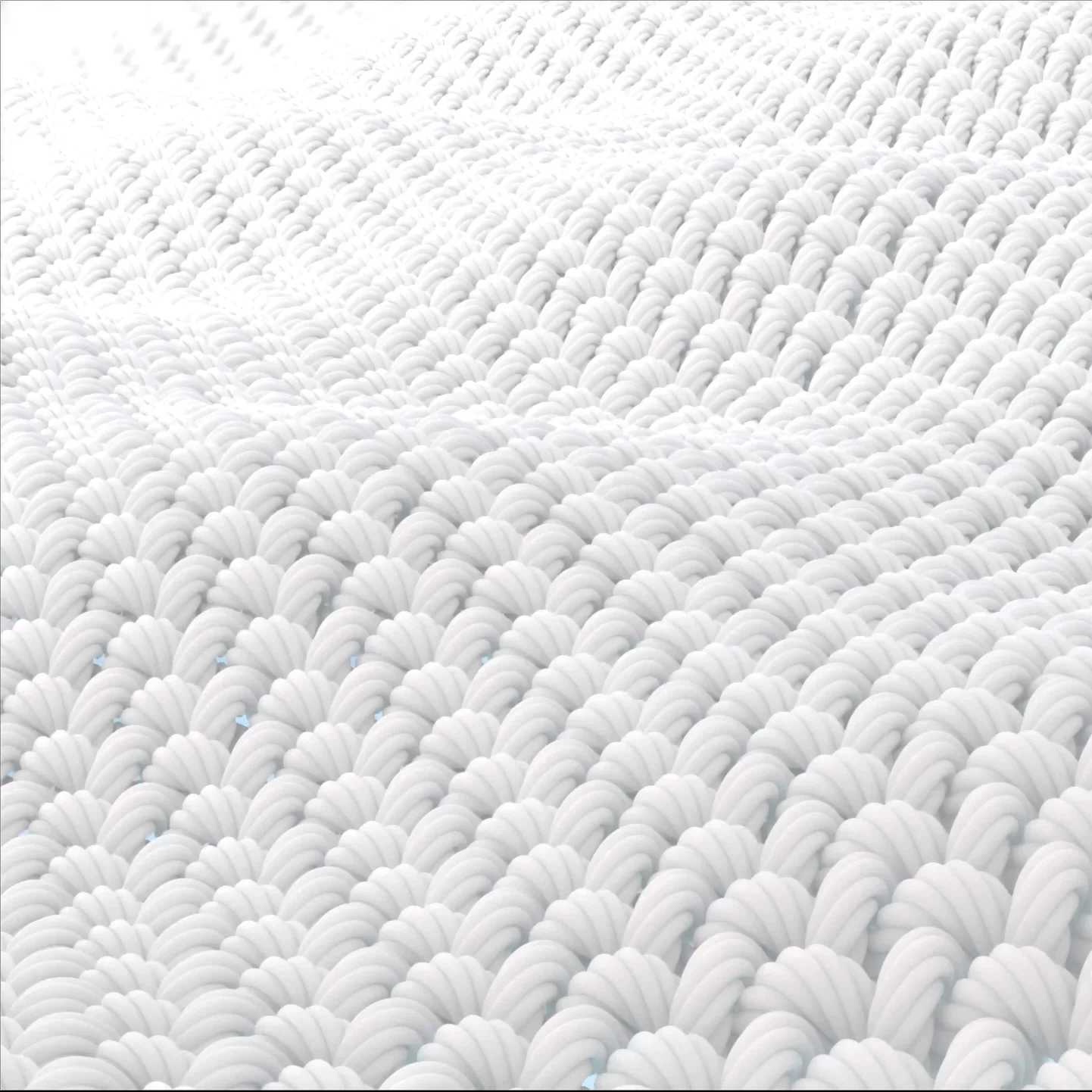

Knitting

Creates flexible structures for soft tissue support.

Weaving

Produces strong, durable fabrics for implants like vascular grafts.

Braiding

Used for tubular structures in sutures and ligatures.

Non-Woven Textiles

Often used in wound care products for their absorption and protective properties.

Advantages

Advantages

Biomedical textiles offer several benefits

in medical device manufacturing

Biomedical textiles offer several benefits

in medical device manufacturing

Customization

Textiles can be engineered to meet specific mechanical and biological requirements.

Minimally Invasive Applications

Textile-based devices allow for less invasive surgical procedures, reducing recovery time.

Biocompatibility

Engineered materials ensure safe interactions with body tissues.

Innovation

Advancements in textile engineering contribute to cutting-edge applications like tissue regeneration and bioactive scaffolds.

Two-dimensional and Three-dimensional Braiding

Used to create tubular structures like sutures, catheters, and stents. It offers flexibility and strength, ideal for medical applications that require both.

Customization

Textiles can be engineered to meet specific mechanical and biological requirements.

Minimally Invasive Applications

Textile-based devices allow for less invasive surgical procedures, reducing recovery time.

Biocompatibility

Textile-based devices allow for less invasive surgical procedures, reducing recovery time.

Innovation

Advancements in textile engineering contribute to cutting-edge applications like tissue regeneration and bioactive scaffolds.

therapeutic fields, including cardiovascular,orthopaedics, wound healing, and tissue engineering.

Biomedical textiles are a critical component of the medical industry, contributing to patient care in a wide range of therapeutic fields,

including cardiovascular, orthopaedics, wound healing, and tissue engineering.

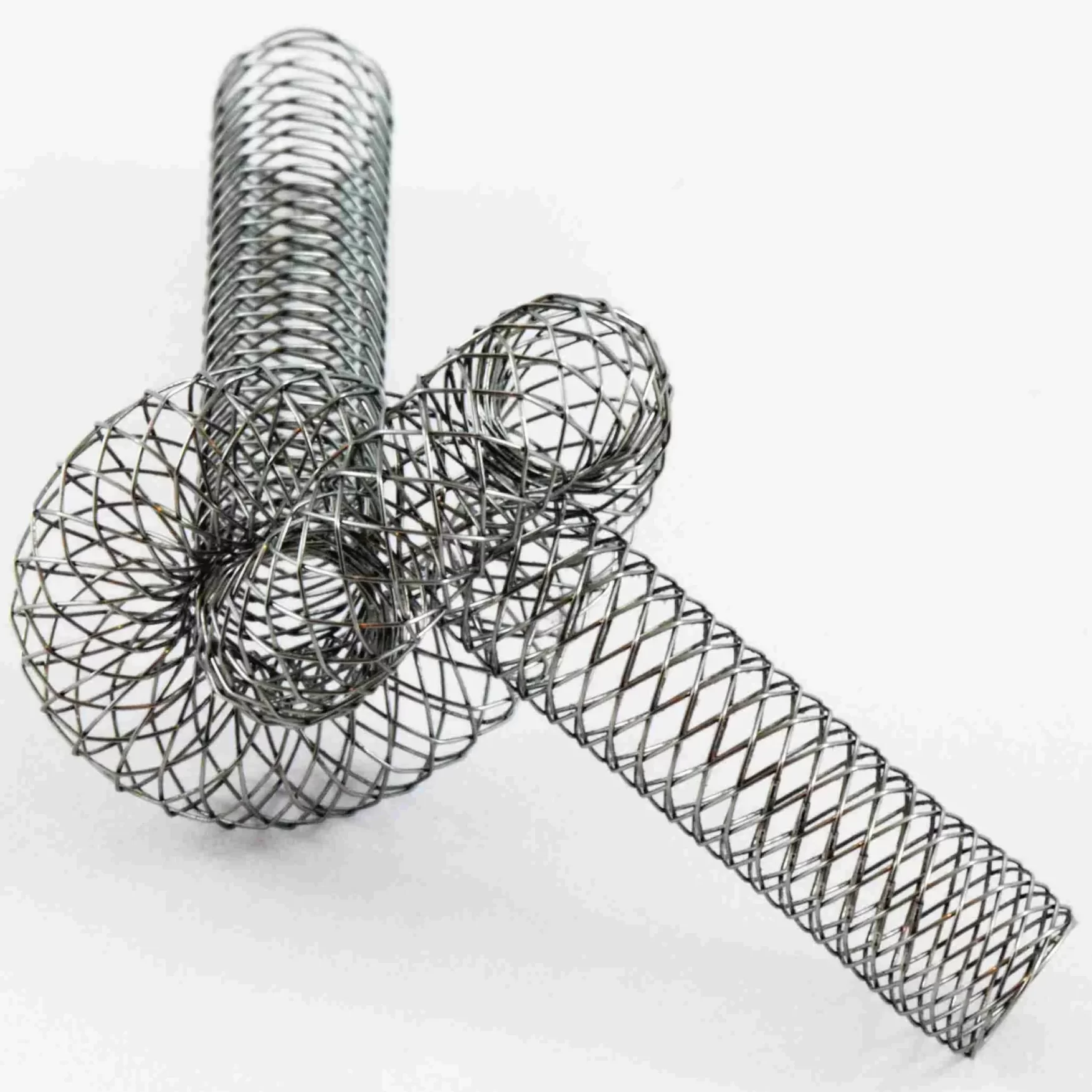

About Braiding

Braiding is a specialized technique used in the fabrication of biomedical textiles, where multiple strands of fibres are interlaced diagonally to form tubular or flat structures. This method is ideal for creating products that require high tensile strength and flexibility, such as sutures, stents, vascular grafts, and ligatures. Braided structures are used to day for minimally invasive procedures and as stents due to their unique capability to reduce its diameter due to axial elongation . The braiding process allows for customization of thickness, material choice, and performance characteristics to suit specific medical needs.

Key Applications

- Sutures and ligatures: Flexible and strong braided structures for wound closure.

- Self expandable nitinol stents

- Occluders

- Catheters and stents: Braided designs provide structural integrity and flexibility in minimally invasive devices.

Advantages of Braiding

- Strength and Flexibility: The interlaced fibres provide superior mechanical properties.

- Biocompatibility: Materials such as polyester, Nitinol ,Cobalt Chrome .

- Braided biomedical textiles play a vital role in medical device manufacturing, especially in applications requiring flexibility, strength, and biocompatibility.

Types of Braiding Technology in Biomedical Textiles

Each technique is chosen based on the functional and mechanical needs of the final medical product, ensuring durability, biocompatibility, and optimal performance.

Our lightweight, high-performance medical braids deliver exceptional strength comparable to steel, while offering superior flexibility. These braids are designed to meet the rigorous demands of the medical field, combining robustness with ease of use for applications requiring both durability and pliability. With advanced braiding technologies, our braids ensure precision, adaptability, and reliable performance, making them ideal for sutures, vascular grafts, and other implantable devices where both strength and flexibility are critical for success.

1. Round Braiding: Used to create tubular structures like sutures, catheters, and stents. It offers flexibility and strength, ideal for medical applications that require both.

2. Flat Braiding: Produces flat, ribbon-like structures, often used in ligatures and specialized wound closures where surface area matters.

4.Two-dimensional and Three-dimensional Braiding:These advanced braiding technologies allow for more complex geometries, providing enhanced strength and customizable designs for implants, scaffolds, and other medical devices.