Assembly & Fabrication

Biomedical textile assembly and fabrication involve integrating and constructing textiles into functional medical devices or components.

This process typically includes several key stages

This process typically includes several key stages

Design and Prototyping

- Conceptualization: Define the medical device’s requirements and desired textile properties.

- Prototyping: Create initial designs and prototypes to test and refine textile performance.

Material Selection

- Fiber Choice: Select appropriate medical-grade fibres based on the required mechanical and biocompatibility properties (e.g., ultra-high molecular weight polyethylene, polyester, polypropylene).

- Combination of Materials: Decide whether to use a single type of fibre or a blend to achieve specific characteristics.

Textile Formation

- Knitting/Braiding/Weaving: Use the chosen technique to form the textile. Each method has unique benefits depending on the application (e.g., flexibility, strength, or structural integrity)..

Post-Processing

- Surface Treatments: Apply coatings or treatments to enhance properties such as antimicrobial resistance or moisture management.

- Sterilization:Ensure the textiles are sterilized to meet medical standards and be safe for implantation or use in medical procedures.

Assembly

- Cutting and Shaping: Cut the textile into required shapes and sizes based on the device design.

- Joining Techniques: Employ techniques like stitching, bonding, or welding to assemble the textile components into the final device.

Integration with Other Components

- Component Integration: Incorporate the textile into a larger medical device or system, ensuring compatibility with other materials or electronic components.

- Functional Testing: Test the assembled device to ensure it meets all performance, safety, and regulatory requirements.

Quality Control and Validation

- Inspection: Perform rigorous inspections to check for defects or inconsistencies in the textile and assembly.

- Validation: Conduct tests to validate that the final product performs as intended in medical applications.

Regulatory Compliance

- Documentation: Prepare and maintain documentation for regulatory approval, including details of material specifications, fabrication methods, and testing results.

- Certification: Obtain necessary certifications to comply with medical device regulations and standards.

Design and Prototyping

- Conceptualization: Define the medical device’s requirements and desired textile properties.

- Prototyping: Create initial designs and prototypes to test and refine textile performance.

Material Selection

- Fiber Choice: Select appropriate medical-grade fibres based on the required mechanical and biocompatibility properties (e.g., ultra-high molecular weight polyethylene, polyester, polypropylene).

- Combination of Materials: Decide whether to use a single type of fibre or a blend to achieve specific characteristics.

Textile Formation

- Knitting/Braiding/Weaving: Use the chosen technique to form the textile. Each method has unique benefits depending on the application (e.g., flexibility, strength, or structural integrity)..

Post-Processing

- Surface Treatments: Apply coatings or treatments to enhance properties such as antimicrobial resistance or moisture management.

- Sterilization:Ensure the textiles are sterilized to meet medical standards and be safe for implantation or use in medical procedures.

Assembly

- Cutting and Shaping: Cut the textile into required shapes and sizes based on the device design.

- Joining Techniques: Employ techniques like stitching, bonding, or welding to assemble the textile components into the final device.

Integration with Other Components

- Component Integration: Incorporate the textile into a larger medical device or system, ensuring compatibility with other materials or electronic components.

- Functional Testing: Test the assembled device to ensure it meets all performance, safety, and regulatory requirements.

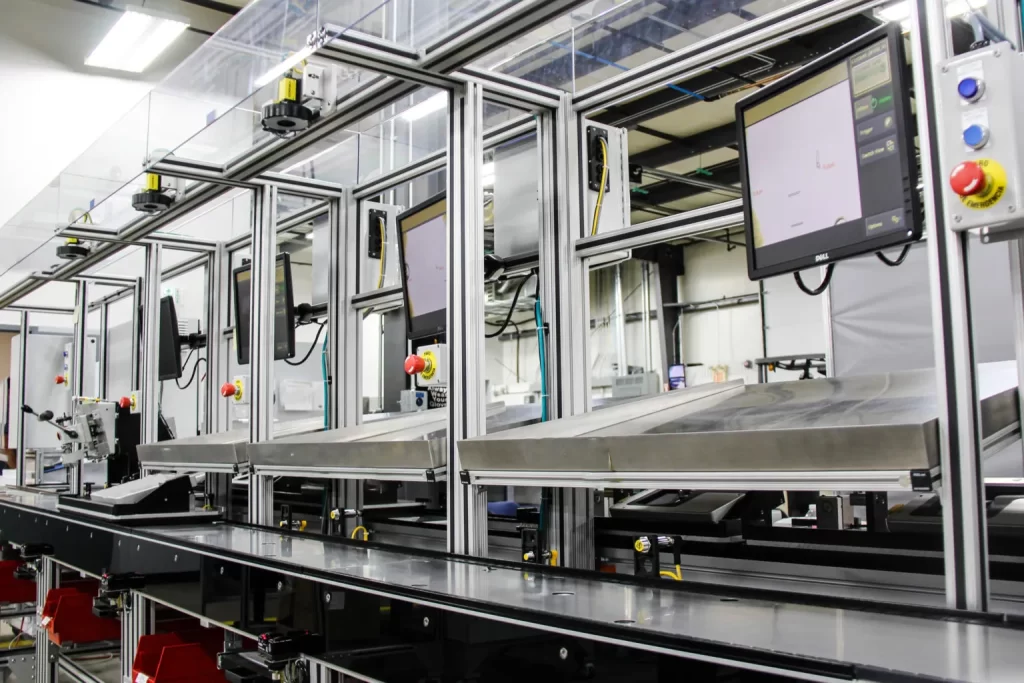

Quality Control and Validation

- Inspection: Perform rigorous inspections to check for defects or inconsistencies in the textile and assembly.

- Validation: Conduct tests to validate that the final product performs as intended in medical applications.

Regulatory Compliance

- Documentation: Prepare and maintain documentation for regulatory approval, including details of material specifications, fabrication methods, and testing results.

- Certification: Obtain necessary certifications to comply with medical device regulations and standards.

Innovating through unique fabrications allows our engineers to deliver game-changing solutions for common surgical challenges. For example, our braided loops are ideal for orthopaedic applications, offering the perfect combination of size, flexibility, and strength for use in various orthopaedic and arthroscopic procedures.

Our expertise in terminations ensures that our products seamlessly interface with actuators, anchors, and other devices, fully leveraging the benefits of our braids.

Whether you need loops, eye splices, or control cables, we can help you develop, innovate, manufacture, and deliver tailored solutions to meet your needs.